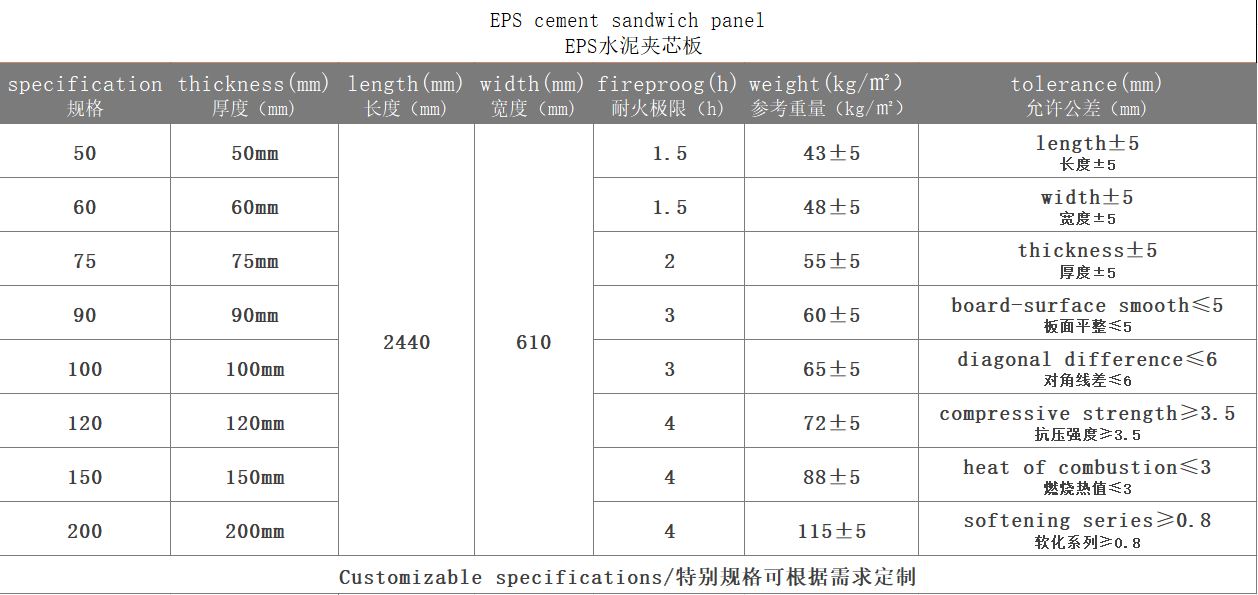

EPS cement sandwich panel

do you have a construction project we can help with?

EPS cement sandwich panel

EPS cement sandwich panels are lightweight composite boards consisting of thin fiber cement boards or calcium silicate boards as facing layers and lightweight core materials as the central layer. These products exhibit unparalleled comprehensive advantages over other wall materials, including solid structure, lightweight, thin profile, high strength, impact resistance, superior load-bearing capacity, thermal insulation, soundproofing, fire resistance, waterproofing, easy cutting, and minimal self-weight. They are primarily used as partition walls, interior and exterior walls, and fire-rated partitions in buildings.

These panels effectively reduce wall thickness, increase usable floor area, decrease structural load, enhance seismic resistance and safety performance, and lower overall construction costs, making them the optimal alternative to traditional building materials.

Applications:

- Widely used in various new and existing non-load-bearing interior and exterior partition walls

- Suitable for industrial building fire walls and non-load-bearing walls

- Applicable to interior and exterior walls of steel structure buildings

- Ideal for building renovation projects with specific wall load-bearing requirements

- Appropriate for environments demanding high fire resistance, sound insulation, and moisture protection.

Construction site photographs

Product Features:

1. Superior Thermal Insulation Performance

The EPS (Expandable Polystyrene) foam core is an excellent thermal insulation material with an extremely low thermal conductivity coefficient (typically ranging from 0.03 to 0.04 W/(m·K)), making it particularly suitable for factories, warehouses, cold storage facilities, prefabricated houses, and clean rooms requiring high insulation standards.

2. Lightweight yet High Strength

Compared to traditional brick or concrete walls, these panels weigh only 1/10 to 1/15, significantly reducing structural load while maintaining excellent compressive, bending, and impact resistance, meeting wall strength requirements. They are especially suitable for high-rise buildings, additional story constructions, and areas with poor geological conditions.

3. Outstanding Fire Resistance

The panels can achieve A2-grade (non-combustible material, minimal heat release) or B1-grade fire resistance standards, meeting most building fire safety requirements.

4. Excellent Seismic Performance

With minimal self-weight, they generate low inertia forces during earthquakes. The integrated wall structure formed after installation demonstrates superior seismic performance compared to traditional masonry structures.

5. Effective Soundproofing

The cement mortar surface layers provide mass, while the EPS core material offers damping and sound absorption, meeting general industrial and civil construction soundproofing requirements.

6. Eco-friendly and Energy-efficient

Main components (cement, sand, steel, EPS) are recyclable, and the construction process is predominantly dry, reducing construction waste and dust pollution.

7. Rapid and Convenient Installation

Standardized factory production ensures consistent quality. On-site assembly eliminates the need for wet processes like bricklaying and plastering, is weather-independent, and achieves construction speeds several times to over ten times faster than traditional methods, significantly reducing project timelines.

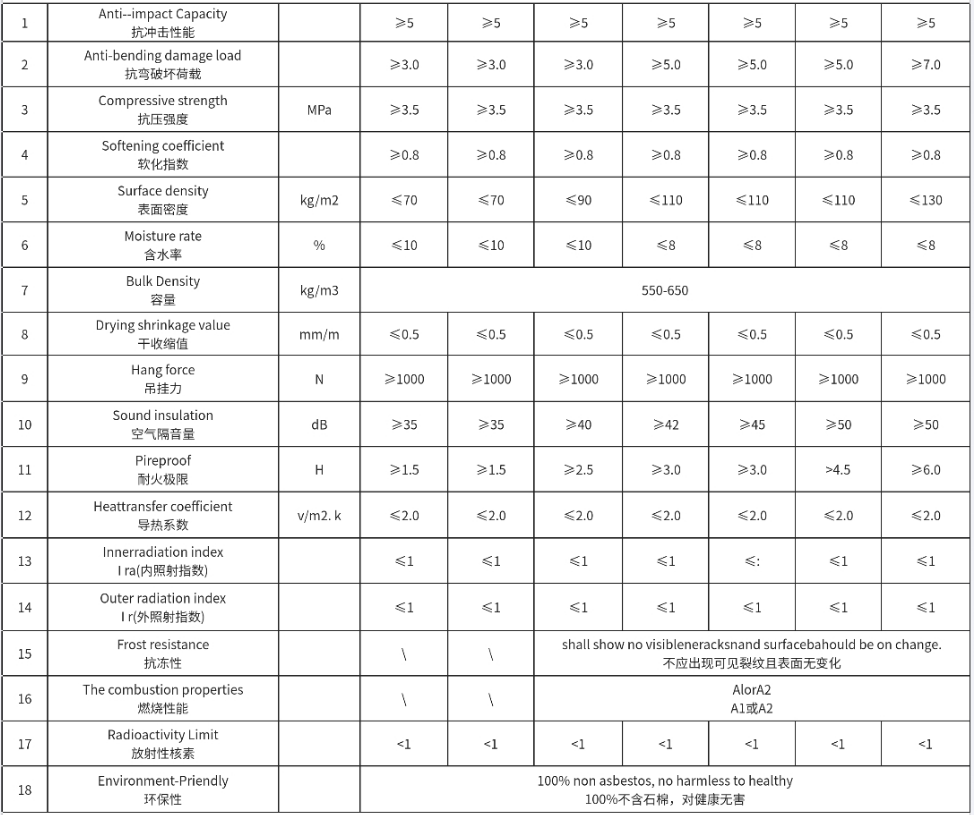

Performance Indicators:

Get A Quote Today

At vero eos et accusamus et iusto odio dignissimos ducimus qui blanditiis praesentium voluptatum deleniti atque corrupti quos dolores et quas.