EPS Foam Sandwich Wall Panels

do you have a construction project we can help with?

Energy-Saving EPS Foam Sandwich Wall Panels for Roofing & Exterior Walls

Product Introduction

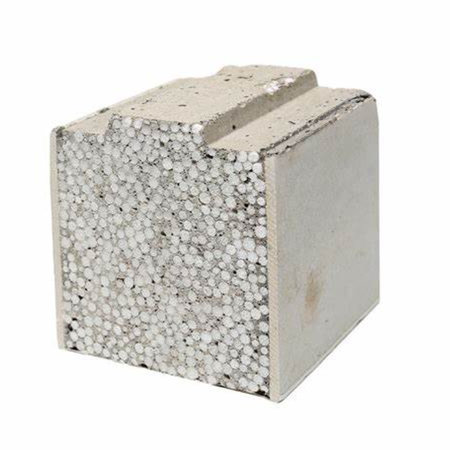

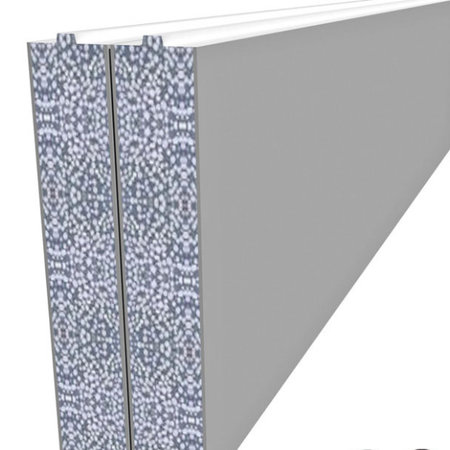

Our EPS (Expanded Polystyrene) Foam Sandwich Panels are engineered for superior thermal insulation, lightweight durability, and rapid installation—making them the ideal choice for modern energy-efficient roofing and exterior walls. These panels feature a three-layer composite structure: high-strength outer surfaces (metal/cement fiber) bonded to a fire-resistant EPS foam core, delivering exceptional heat preservation, soundproofing, and weather resistance. Perfect for residential, commercial, and industrial projects seeking cost-effective, eco-friendly building solutions.

Technical Specifications

| Parameter | Value / Description | Testing Standard |

| Panel Thickness | 50mm, 60mm,75mm, 100mm, 120mm, 150mm,200mm (customizable) | ASTM C1289 |

| Panel Size | 1200mm × 2400mm (standard), up to 6000mm length | ISO 8335 |

| Density (EPS Core) | 18-30 kg/m³ | ASTM D1622 |

| Compressive Strength | ≥0.15 MPa (EPS core) | ISO 844 |

| Thermal Conductivity | 0.033-0.038 W/(m·K) | ASTM C518 |

| Fire Rating | Class A (Non-combustible) | ASTM E84 / EN 13501-1 |

| Sound Insulation | 40-45 dB (for 100mm panel) | ISO 10140 |

| Water Absorption | ≤10% (by volume) | ASTM C272 |

| Bending Strength | ≥5 MPa (full panel) | ASTM C393 |

| Weight | 15-25 kg/m² (depending on thickness) |

Key Advantages

- Ultra-Lightweight – 50% lighter than traditional materials, reducing structural load and labor costs.

- Energy-Efficient – EPS core minimizes heat transfer, cutting heating/cooling costs by up to 40%.

- Fireproof & Safe – Class B1 fire rating (ASTM E84) with self-extinguishing foam core.

- Weather-Resistant – Withstands extreme temperatures (-30°C to +80°C), UV rays, and moisture.

- Noise Reduction – 30dB+ sound insulation for quieter interiors.

- Easy Installation – Prefabricated panels install 3x faster than conventional materials.

- Eco-Friendly – Recyclable materials, compliant with LEED & BREEAM standards.

Applications

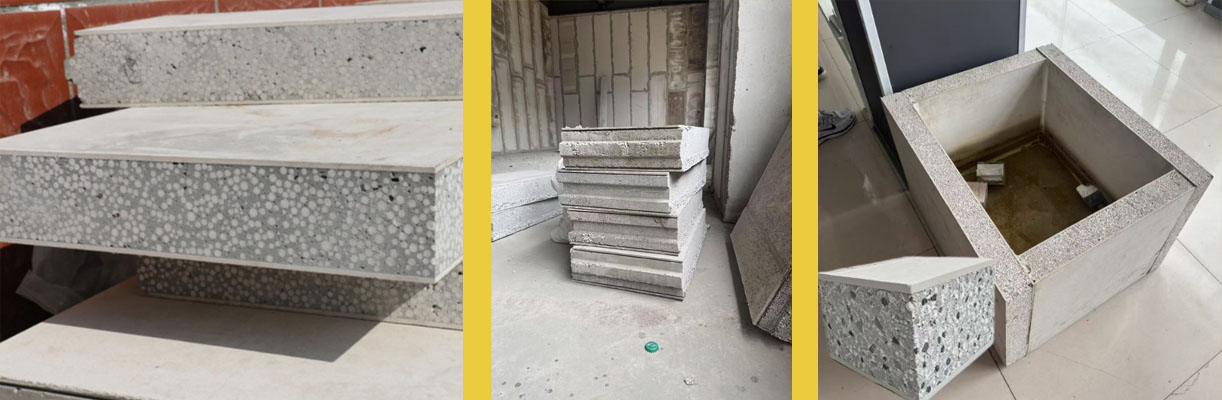

- Residential – Roofing, exterior walls, balconies, and prefab homes.

- Commercial – Offices, shopping malls, hotels, and cold storage facilities.

- Industrial – Warehouses, factories, cleanrooms, and logistics centers.

- Green Buildings – Solar panel roofs, passive houses, and eco-communities.

Comparison vs. Traditional Materials

| Feature | EPS Sandwich Panel | Brick Wall | Concrete Panel |

| Weight (kg/m²) | 15-25 | 180-220 | 200-250 |

| Thermal Insulation | Excellent (0.033 W/m·K) | Poor | Moderate |

| Installation Time | 1-2 days per house | 2-4 weeks | 3-6 weeks |

| Fire Resistance | Class A | Class A | Class A |

| Cost Efficiency | 30% cheaper | High labor cost | High material cost |

Construction site photographs

Installation Guidelines

- Foundation Preparation – Ensure a level base.

- Panel Alignment – Use laser level for precision.

- Mechanical Fixing – Screws/anchors every 400mm.

- Joint Treatment – Seal with elastic mortar.

- Surface Finishing – Paint, tiles, or cladding.

Certifications & Compliance

- ISO 9001, CE, SGS, ASTM, EN standards.

- Green Building Certifications (LEED, BREEAM).

FAQs

Q: Can it be used in seismic zones?

Yes – Flexible EPS core absorbs vibrations.

Q: How long does it last?

50+ years with proper maintenance.

Conclusion

The EPS Cement Sandwich Panel is a revolutionary building material that combines lightweight strength, energy efficiency, and rapid construction. It is ideal for modern, sustainable, and cost-effective projects.

Get A Quote Today

At vero eos et accusamus et iusto odio dignissimos ducimus qui blanditiis praesentium voluptatum deleniti atque corrupti quos dolores et quas.