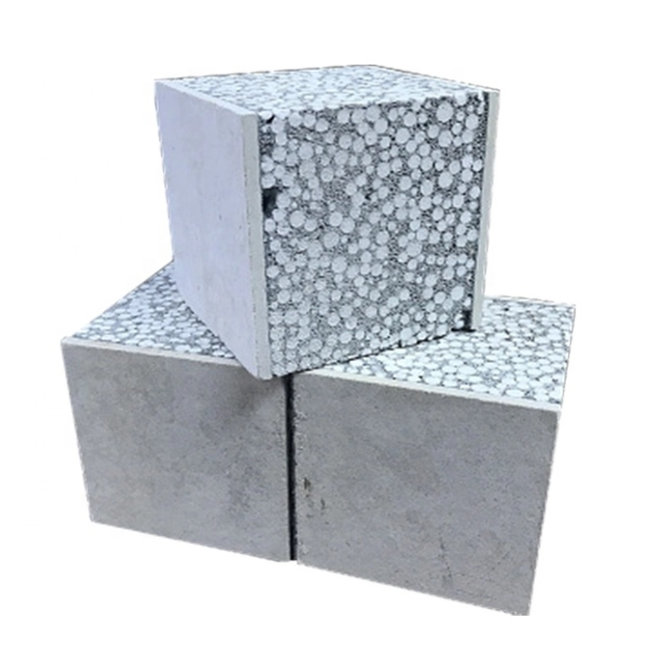

EPS Cement Sandwich Panels for Exterior Walls

do you have a construction project we can help with?

Fast Installation Interlock EPS Cement Sandwich Panels for Exterior Walls & Prefabricated Houses

Product Introduction

Fast Installation Interlock EPS Cement Sandwich Panels revolutionize modern construction with their high-strength, energy-efficient, and easy-to-assemble design. These panels feature a unique interlocking system that ensures seamless, weatherproof connections, significantly reducing installation time. The EPS foam core is sandwiched between reinforced cement fiber boards, providing superior insulation, fire resistance, and durability—perfect for prefabricated houses, commercial buildings, and industrial structures.

Product Specifications

| Parameter | Specification |

| Core Material | Expanded Polystyrene (EPS) Foam (Density: 14-20kg/m³) |

| Surface Material | Reinforced Cement Fiber Board |

| Panel Thickness | 60mm – 200mm (Customizable) |

| Panel Width | 600mm – 1200mm |

| Panel Length | Up to 6m (Pre-cut options available) |

| Thermal Conductivity | 0.035 W/m·K |

| Fire Rating | Class A (ASTM E84) |

| Compressive Strength | ≥1200kg/m² |

| Sound Insulation | ≥30dB |

| Water Absorption | ≤5% |

| Operating Temperature | -40°C to +70°C |

Key Advantages

- Lightweight Yet Strong – High load-bearing capacity without heavy structural support.

- Thermal & Sound Insulation – EPS core ensures low thermal conductivity (0.035 W/m·K) and 30dB+ noise reduction.

- Fireproof & Waterproof – Class A fire rating (ASTM E84) and moisture-resistant surface.

- Customizable Sizes & Finishes – Available in various thicknesses, colors, and textures.

- Low Maintenance – Resistant to corrosion, mold, and pests.

Applications

- Prefabricated Houses – Fast assembly for modular homes, villas, and temporary shelters.

- Commercial Buildings – Offices, hotels, and schools requiring quick, energy-efficient walls.

- Industrial & Warehouse Structures – Durable, insulated walls for factories and storage units.

- Disaster-Resistant Housing – Ideal for earthquake-prone and extreme climate regions.

- Green Buildings – Supports LEED & BREEAM certifications for sustainable construction.

Comparison vs. Traditional Materials

| Feature | EPS Sandwich Panel | Brick Wall | Concrete Panel |

| Weight (kg/m²) | 15-25 | 180-220 | 200-250 |

| Thermal Insulation | Excellent (0.033 W/m·K) | Poor | Moderate |

| Installation Time | 1-2 days per house | 2-4 weeks | 3-6 weeks |

| Fire Resistance | Class A | Class A | Class A |

| Cost Efficiency | 30% cheaper | High labor cost | High material cost |

Construction site photographs

Installation Guidelines

- Foundation Preparation – Ensure a level base.

- Panel Alignment – Use laser level for precision.

- Mechanical Fixing – Screws/anchors every 400mm.

- Joint Treatment – Seal with elastic mortar.

- Surface Finishing – Paint, tiles, or cladding.

Certifications & Compliance

- ISO 9001, CE, SGS, ASTM, EN standards.

- Green Building Certifications (LEED, BREEAM).

FAQs

Q: Can it be used in seismic zones?

Yes – Flexible EPS core absorbs vibrations.

Q: How long does it last?

50+ years with proper maintenance.

Conclusion

The EPS Cement Sandwich Panel is a revolutionary building material that combines lightweight strength, energy efficiency, and rapid construction. It is ideal for modern, sustainable, and cost-effective projects.

Get A Quote Today

At vero eos et accusamus et iusto odio dignissimos ducimus qui blanditiis praesentium voluptatum deleniti atque corrupti quos dolores et quas.