- Installation Sequence: Commence installation typically from one end of the wall (e.g., adjacent to the main wall or column), proceeding sequentially towards the opposite end; alternatively, initiate from the doorway and extend towards both sides. Prioritize the installation of full panels followed by supplementary panels.

- Application of Bonding Mortar: Uniformly apply a layer of specialized polymer bonding mortar on the upper (top), lower (bottom), and side edges (tongue-and-groove joints) of the panels. Application thickness: approximately 5-10mm (as per manufacturer specifications). Ensure the mortar fills the groove recesses completely. Similarly, apply bonding mortar to the base layers where panels contact the floor, ceiling, and side walls.

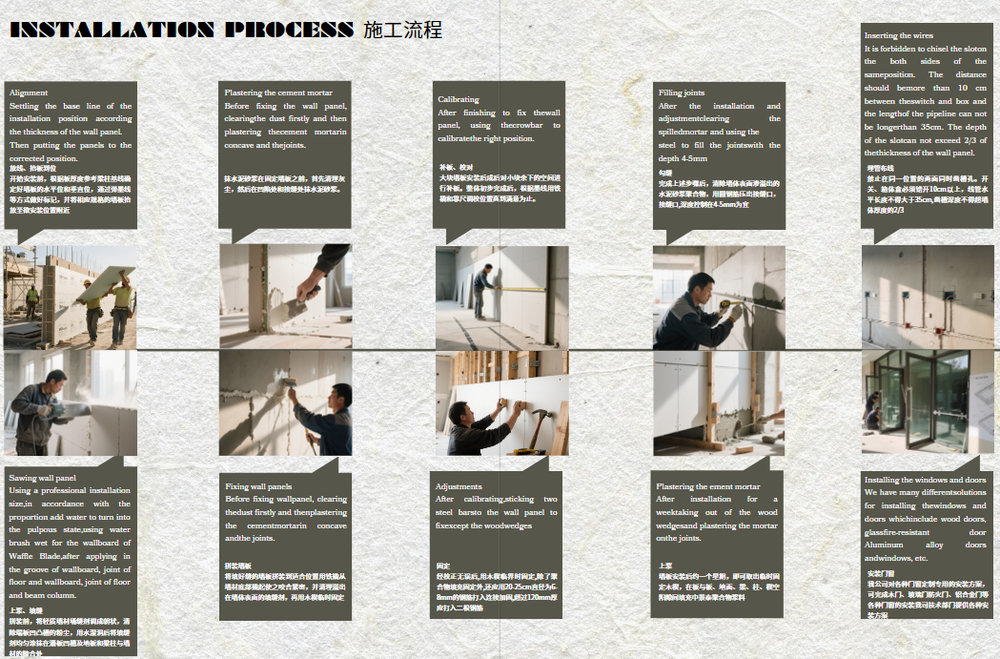

- Panel Installation: Lift the mortar-coated panels, align them with the pre-marked floor and ceiling installation lines, and position them vertically and steadily. Utilize a pry bar to adjust positioning, ensuring tight alignment of the panel bottom, top, and side tongue-and-groove joints with adjacent panels/base layers. Gently tap the panel surface (avoid direct impacts on edges) using a rubber or wooden mallet to secure the panel and allow excess mortar to emerge at joints, while verifying wall verticality and flatness with a level and straightedge. Ensure seamless and aligned vertical joints (tongue-and-groove joints) between panels.

- Bottom Fixation (Optional, Recommended): Temporarily wedge wooden blocks at the panel’s lower contact points with the floor (typically at both ends and center) to aid in vertical adjustment and positioning. After the bonding mortar attains sufficient strength (usually 24-48 hours), remove the wedges and fill the wedge holes with mortar. Alternatively, secure the panel base to the floor using a nail gun with U or L-shaped brackets (requiring pre-embedment or direct application to the base layer).

- Top Fixation (Critical): The gap between the panel top and beam/floor slab (approximately 20-40mm) is pivotal. This gap must not be filled with bonding mortar. After panel positioning and vertical adjustment, wedge wooden blocks on both sides of the panel top (applying moderate force to prevent deformation or cracking). Once the bonding mortar fully hardens (typically 24-48 hours), remove the wedges. Fill the gap with elastic material (e.g., polyethylene or polyurethane foam rods) to a depth of about 20-30mm. Finally, seal and level the top joint surface with specialized joint compound or elastic sealant (e.g., silicone sealant), a crucial measure to prevent future joint cracking.

- Door and Window Opening Reinforcement: Employ full panels on both sides of door and window openings, and install lintel panels above. The lintel panel should extend into the adjacent walls by no less than 100mm (as per design specifications). Reinforce the connection between the opening edge panels, lintel panels, and door/window frames with galvanized steel plates (L or U-shaped), steel mesh, or specialized connectors, in addition to applying bonding mortar.

- Corner and T-Joint Treatment: At corners, stagger the panel joints of adjacent walls (i.e., panel joints of one wall should not align with those of the other). Reinforce corners with pre-embedded L-shaped steel plates or fiberglass mesh. At T-joints, ensure the connecting panel end is neatly cut and bonded tightly to the main wall panel with mortar. Strengthen with connectors (e.g., U-shaped brackets) or by laying fiberglass mesh.

- Pre-embedding of Water and Electrical Conduits: Perform conduit routing after panel installation and initial setting of the bonding mortar (to minimize panel disturbance). Use a grooving tool or cutter to create grooves along marked lines on the panel surface. Groove depth must not exceed one-third of the panel thickness, and width should be moderate. Avoid multiple parallel deep grooves or intersecting grooves at the same location. After conduit installation, fill and level the grooves promptly with specialized joint compound or polymer mortar, immediately overlaying alkali-resistant fiberglass mesh (extending ≥50mm beyond each groove edge) for crack resistance enhancement.

4 Comments

Leave A Comment

Tags

best blade for cement board

building materials

cement board panels

cement board vs fiber cement board

cement wall panels

cement wall panels Factory

construction materials

construction materials comparison

cutting fiber cement siding

durable building materials

EPS cement Panel

eps cement sandwich panel

eps cement sandwich panels

eps cement wall panels

fiber cement board

fiber cement board advantages

fiber cement board applications

fiber cement board benefits

fiber cement board cost per square foot

fiber cement board cutting

fiber cement board fire rating

fiber cement board for interior walls

fiber cement board installation

fiber cement board installation cost

fiber cement board installation guide

fiber cement board installation tips

fiber cement board lifespan

fiber cement board maintenance

fiber cement board uses

fiber cement durability

fiber cement fire rating

fiber cement installation guide

fiber cement installation tips

fiber cement rainscreen system

fiber cement siding

fiber cement siding benefits

fiber cement siding cost

fiber cement siding cost per sq ft

fiber cement siding durability

fiber cement vs vinyl siding

fiber cement wall panels cost

fire-resistant materials

OEM/ODM fiber cement board Supplier China

sustainable building materials

Wholesale EPS cement Panel

8esnsv

The installation is very simple, just put the wall panel into the U-shaped card slot, fix it with a nail gun, and smear the place where it is connected with cement. You can add my contact information, and I will send you the product catalog and installation video.

whats////app: +86 19006548904

E////mail: yuny@syreps.com

TaiXiuSuarewin… Alright, I wanna win big time! Any tips from the pros on this site? Bring on the lucky dice! taixiusuarewin

Hello TaiXiuSuarewin, thank you for your question. I will arrange for our business manager to contact you. Please keep an eye on your email.😀